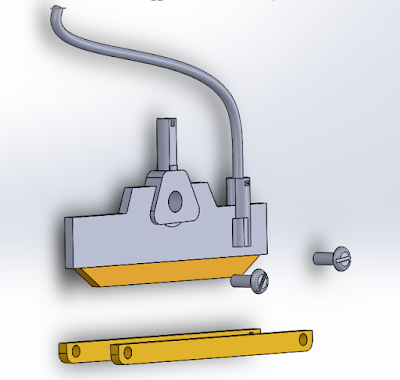

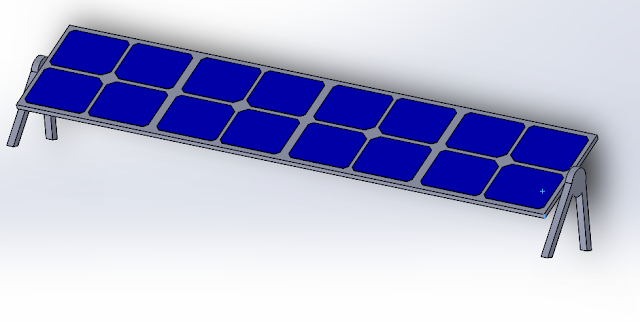

Week 8: For this week, I continue working on waysides. My goal is to finish it by Tuesday ( July 23, 2017). I also find a better way to rotate the solar panels. Instead of design a mechanism to rotate solar panels 180 degree, I think it is better to have it rotated around a pivot point. A motor will be installed under the solar panel and programmed so that it can rotate at a certain angle. My goal for this design is to get as much sunlight as possible, so that the solar panel can generate 50V output.